Top 5 unique challenges of designing underground structures

- Si Shen

- Mar 9, 2021

- 3 min read

An ‘arty’ design process

In structural engineering, engineers are usually dealing with man-made materials, which are subject to rigorous material selection, refinement and quality check processes. We know their exact properties hence can produce accurate calculations. However, in the underground world, we are dealing with materials created by the mother nature. The material can be different from place to place and often times strikes the engineer by surprise. In the underground world, being apparently accurate in the calculation process is usually meaningless. A relatively large amount of engineering judgement based on past experience and best practice has to be applied. Sound risk-based engineering judgement should be placed at a greater level of importance than the accuracy of the calculation and analytical process. Therefore in calculations and analysis, we must be result-oriented and know what makes the real difference and must be as accurate as possible, whilst for other less important things we can afford to be less accurate. Making this judgement requires experience.

Soil-structure interaction

The ground imposes stress onto the structure (as explained in this post https://www.si-eng.org/post/soil-structure-interaction-2-lateral-earth-pressure) , but at the same time the ground has its own structural capacity acting in composite to that of the structure, thus contributing to the overall structural capacity. The exact share of load between the ground and the structure depends on their relative mechanical behaviour (e.g. stiffness). In some cases where the ground is very competent, the structure is actually intentionally designed to be flexible in order to fully mobilise the capacity of the ground – a good example being sprayed concrete lining for tunnels in competent rock.

This previous blog post https://www.si-eng.org/post/soil-structure-interaction-1-what-interaction explains the soil-structure interaction in more details.

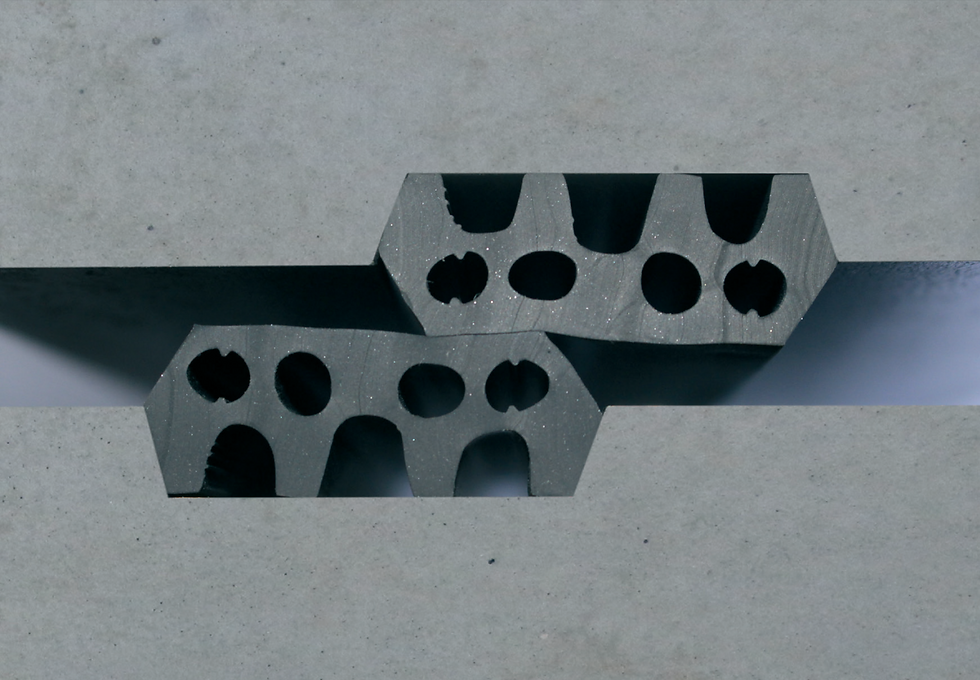

Water resistance

Ground water exists in the voids of soil and rocks, and engineers that creates useable underground spaces usually have to make sure water is kept out of the structure. Waterproofing can be achieved via multiple means, such as membrane (sheet or sprayed), cavity drainage or crack control of concrete. Sometimes the approach of waterproofing has to switch from one to another, which calls for a sound transitional detail. Even if a single approach is used everywhere, we must ensure waterproofing is delivered as a holistic system without any weak points. 9 out of 10 water leaks through joints, whether it is construction joints or movement joints. Therefore the vast majority of waterproofing design is about detailing. Do not try to out-smart water; keep it simple and stupid (KISS). This previous blog gives a few tips about waterproofing membrane design. https://www.si-eng.org/post/what-structural-engineers-need-to-know-about-waterproofing-membrane

Ground treatment

Ground treatment is a process of changing one of a number of mechanical properties of the ground, such as permeability, stiffness, strength, density, etc. As noted above, since the ground itself acts in composite with the structure, improving the ground can achieve the same results as improving the structure itself. Ground treatment could also be used to either prevent or remediate side effects due to construction (such as ground movement). Ground treatment in itself is a vast topic and I plan to write separate blog posts on it.

Restrained shrinkage and deformation effects

Underground structures are mostly chunky concrete elements which could result in a significant amount of heat release at the curing phase and shrinkage over time. This phenomenon was previously called the ‘Early Age Thermal’ effect and now ‘restrained deformation’ by the latest guidance CIRIA C766. This previous post explains the cracking of concrete as a result of restrained shrinkage and deformation https://www.si-eng.org/post/crack-control-of-concrete-using-reinforcement-to-achieve-water-tightness-2

This previous blog provides an overview of CIRIA C766

Comments