The calculation of crack width

- Si Shen

- Apr 13, 2019

- 3 min read

As part of serviceability limit state, cracks within reinforced concrete structural elements are typically required to be controlled down to certain allowable width, for various reasons including water-tightness. This blog explains the requirements for crack width for water retaining structures and some simple tricks to reduce them.

The maximum allowable design crack width may be governed by 4 different factors as listed below.

· Durability. The aggressiveness of the environment of the concrete sits in determines the crack width required. Eurocode calls it ‘exposure class’.

· Aesthetic appearance. Big fat cracks on the concrete surface looks ugly and gets people nervous.

· Water-tightness. The crack width required to achieve self-healing.

· Other (unusual) serviceability requirements, such as radioactivity containment for nuclear reactors or x-ray facilities.

For water-retaining structures, typically the water-tightness is the governing factor.

EC2-3 is typically used for the calculations of crack width for water-retaining structures. As mentioned in my previous blog (https://www.si-eng.org/blog/ciria-guide-c766-preview), there are other ways to achieve water tightness, EC2-3 provides the method to calculate the reinforcement required to achieve water tightness by ‘self-healing’.

The table below shows the typical requirement for water-retaining and water-containment structures.

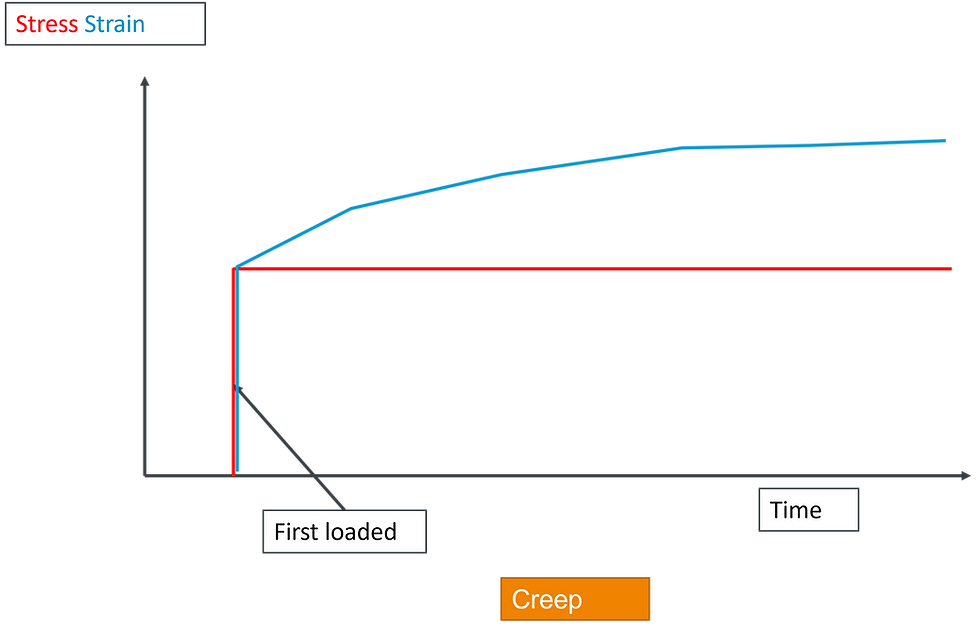

The most fundamental underlying principle for calculating crack width is that crack width = strain X crack spacing, whereas the strain is the differential strain between the reinforcement and the concrete.

From a design perspective, it is always preferable to minimise the crack width wk. To reduce it, we either reduce the crack spacing or the strain.

Minimising strain:

The expression for differential strain in EC2 is:

Which can be converted into the following equation:

Based on this, the following factors affects strain:

• Steel stress

• Steel yield strength/elastic modulus – given, fixed

• Concrete strength/elastic modulus –fctm increases faster than Ecm as grade increases

• Reinforcement area – more reinforcement gives a reduction to strain

• Duration of tension – different factors for long-term and short-term

This means to reduce strain, the following potential measures can be adopted:

• Reduce steel stress – be sure to use the most appropriate serviceability limit state (characteristic, frequent and quasi-permanent), to avoid using overly onerous combination factors for the loads.

• Decrease concrete grade – sometimes possible, but subject to requirements such as durability and compressive capacity

• Put in more reinforcement – enough said

• Substantiate that the tension is short term

Minimising crack spacing:

Smaller crack spacing equals greater number of cracks over the same distance, which helps spread out the deformation. For this reason, smaller crack spacing is desirable.

The expression for crack spacing as given in EC2 is:

This means the following factors influences crack spacing:

• Cover – This is governed by a number of requirements, and is a relatively complicated concept. I plan to write another whole blog just to explain this.

• Reinforcement area

• Bar size

The cover is usually a given and subject to no room for negotiation. Also it is typically not preferred to increase reinforcement area where possible.

Therefore, the usual trick to reduce crack spacing is to use smaller bar size, closer spaced, for the same given reinforcement area. This is because for the same given reinforcement area, smaller bars provides more surface area for bonding between the steel and the concrete, giving the steel more ‘grip’ to control cracking in the concrete.

Furthermore, the new CIRIA guide C766 gives further guidance on concrete cover and complements EC2. My previous blogs touch on this subject:

https://www.si-eng.org/blog/ciria-guide-c766-preview

Comments