Instrumentation and monitoring - an overview

- Si Shen

- Aug 9, 2021

- 4 min read

Instrumentation and monitoring is an essential link of risk management in the cycle of design and construction. It provides valuable indicators that give clues of what’s going on on site. The purpose of monitoring can be:

Safety assurance – to protect the contractor from significant risk of failure, by issuing early warnings, so that contingency actions can be taken. On-site construction is a battlefield, and the designer can be given no time to think and devise a plan on the spot. Therefore contingency measures should be set up beforehand to the largest extent possible, such that they are automatically triggered upon monitoring results meeting certain criterion.

Asset protection – to ‘keep an eye on’ adjacent structures to ensure the damage to them are within the safe and contractual range. The monitoring record also provides evidence of whether the damages to the assets are originated by the construction.

Guiding construction – to reveal unknowns and reduce uncertainties that were present in the original design, so that subsequent construction sequence and supporting structures can be revised. This is also typically called the ‘observational method’ in geotechnical engineering. The ground is notorious uncertain and different from place to place. If the actual ground conditions revealed by monitoring is better than those assumed in the design, for example, the designer may choose to let the construction proceed faster or omit some temporary support.

Design feedback - to review and assess whether and to what degree the design assumptions and predictions have materialised in reality, so that we could learn from it and do better next time. For example, did the expected behaviour fully realise? Was the structure over- or under- designed? It can also provide valuable data for future research.

The monitoring is a holistic system comprising observations and actions (responses). It should be devised with the following questions in mind:

What is the purpose of monitoring? What do we and can we get out of it? We must remember that each monitoring item targets a specific hazard/risk. The monitoring is simply a mitigation measure to a risk. No risk, no monitoring, this is the golden rule.

What engineering parameters to monitor, and what instrument to use for each. The designer should have a priority list of key parameters that influence the design outcome. These parameters should be monitored, if possible, to validate the design. There are usually more than one possible instrument to choose from, and the designer needs to assess the value and efficiency of each to determine the best.

How much is expected for each instrument. The expected reading from each instrument should come from the design output based on certain scenarios. When the actual reading is compared to these expectations, we can hopefully infer: 1) how safe the situation is, 2)what we are really dealing with in real life, and to what degree these tally up with the design assumptions 3) to what degree is the original plan over-designed or under-designed? 4) what could be the root cause of the differences between expectation and reality?

The above observation should lead to an action plan that fits around the design and construction strategy. These plans should be drawn up upfront where foreseeable. For example, what to do if the development trend of the readings exhibits magnifying cycles (which can be extremely dangerous)? Should the designer be on stand-by to review the data and revise the design (the observational method)?

Some commonly seen engineering parameters and the possible instrument to be used for each are listed below:

Vertical ground displacement – Extensometer

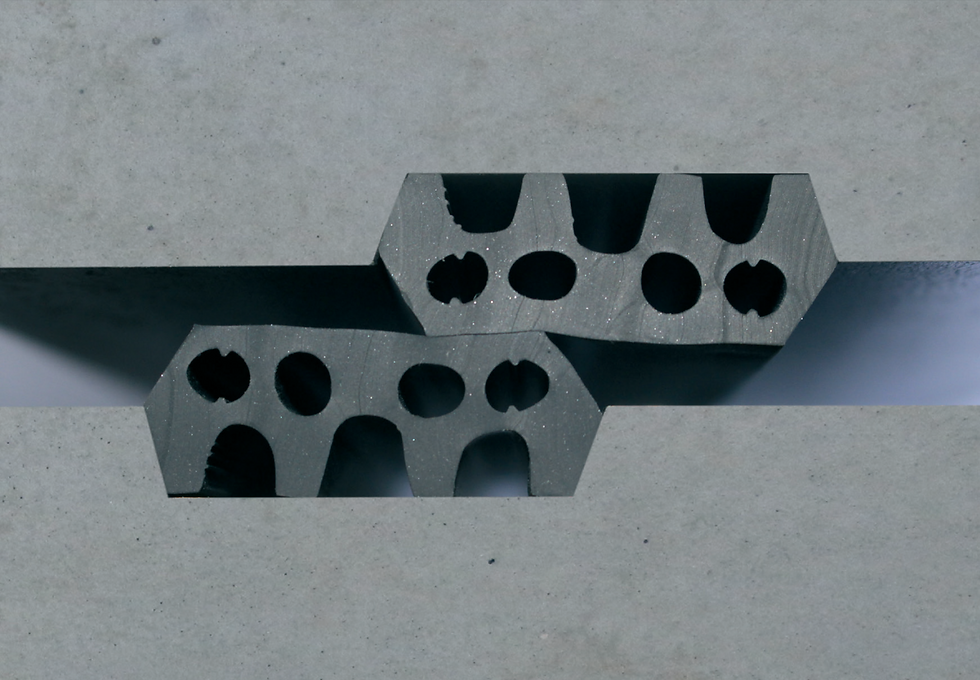

Horizontal ground displacement - Inclinometer

In-plane deformation of a structure (such as change in length) - Strain gauge

Pore pressure – Piezometer

Structure loading – load cell

Pressure on structure – pressure cell

Tunnel convergence - Optic surveying; Tape extensometer

The action plan as mentioned above usually includes a ‘trigger level’ system. The trigger level system is typically 3 to 4 tiered, with traffic light colour coding, namely green, amber, red and sometimes black. How it is set up has no hard and fast rules, and is very much depends on the actual situation, but one possible approach is:

Green trigger level - Realisation of predicted serviceability limit. Monitoring results stopping right on this level means the design is not over-designed. Breaching it means the reality is worse than the expected, but is still safe for now.

Amber trigger level – Mid-way between serviceability and ultimate limit state. Reaching this level means the predicted normal load has been substantially breached and the reality is moving towards the ultimate limit state, starting to cause safety concerns. Frequency of monitoring to be increased. The trend of development of monitored data is of particular importance. Designer notified and design is reviewed, to see if anything should be revised or additional measures should be implemented.

Red trigger level – Approaching the limit of ultimate limit state, with a marginal factor of safety. Construction to proceed at a high degree of conservatism and caution. Construction speed slowed, cycle shortened and support added. Frequency of monitoring increased to the highest standard. Relevant technical experts should be notified to review the situation as a matter of priority.

Black trigger level – Right on the verge of the ultimate limit state prediction, with more than one monitoring results reaching this trigger at the same time as confirmation. Structure is at imminent danger of collapse. Emergency evacuation of site and response actions (such as full backfill of excavation) triggered. Some less risky constructions may choose to omit the black trigger setting.

Comments