A journey of designing ‘self-healing’ concrete

- Si Shen

- May 6, 2019

- 4 min read

All concrete naturally cracks, regardless of whether it is desirable or not, and regardless of measures that you may choose to adopt, in order to prevent it from cracking.

If you come to think about it, it is actually essential that concrete cracks in order to fully utilise reinforcing steel wrapped inside – no crack means the reinforcement in there is doing little if any at all.

However, for underground structures, because water is always out there, when concrete cracks, it leaks, and no one wants that. So providing water-resisting concrete has been a hot topic for underground works for decades. One of the popular ways is the concept of ‘self-healing concrete’. Concrete as a popular construction material has hardly changed in recent decades but the governing design codes have evolved substantially.

The ‘good old days’

My knowledge of The governing design codes back then were BS 8110 and BS8007. CIRIA R91 was used for ‘early-age thermal’ (EAT) design. BS 8007 specified a maximum allowable crack width of 0.2mm for ‘self-healing’ concrete, as long as there is no ‘critical aesthetic appearance requirement’. Extracts from BS 8007:

The age of Eurocodes

Then since late 2000’s we have come to the age of eurocodes. BS 8007 is replaced by EC2-3 and CIRIA has updated its R91 into C660 to bring it in line with Eurocode. A major change from R91 to C660 was that long term effects have become additive to early age thermal effects, which wasn’t the case before, and that makes the design more conservative. Basically ‘early-age thermal’ is no longer just about early age, and no longer just about thermal.

The requirement for self-healing in the eurocodes is also more detailed and more onerous than that in the British standard. Eurocode clearly differentiate between two different types of cracks – through cracks and non-through cracks. When the structural element is subject to a bending moment, one side is in compression and the other side is in tension. Cracks open on the tension side, but do not propagate through the entire section, so the section is still water resistant. But when the section is subject to axial tension, it is a different story. The entire section is in tension. The cracks go through the entire section creating water paths.

Eurocode 2 part 3 has very onerous requirement for design crack width for through cracks. The allowable crack width for through cracks is somewhere between 0.2mm to 0.05mm, depending on how much pressure there is on the structure. The higher the pressure is, the smaller the cracks must be designed to, because they are harder to self heal. Bear in mind that the BS8007 requirement was a constant 0.2mm crack width regardless of pressure.

At high pressure, the requirement for 0.05mm crack width is really difficult to meet by providing reinforcement. You’ve got to put in an amount so huge that sometimes it is simply unbuildable. Recent major projects have shown that very often the enveloped final outcome of reinforcement design is governed by the ‘EAT’ design case, rather than the structural requirements.

We must remember that the principle is to have sufficient rebar to control the crack, but not too much so that concrete can be well compacted. The optimal balance is should be found. When it fails to compact, it has voids which are much worse than cracks. The optimal balance between too little reinforcement and too much reinforcement must be sought by the engineer. Excessive reinforcement is unnecessarily costly, difficult to fix, it is safety hazard for the workers. you have less quality control, Because can’t see what’s going on down there.

A new era

So based on the feedbacks from the industry over the years, in 2012 CIRIA decided to update C660 by the same author. Note the title has changed. It is called control of cracking caused by restrained deformation. In my opinion this name is a lot more accurate than the previous one because concrete does not know what made it crack. Early age thermal is only an element to it.

Some very brief points to explain the key updates in C766. I won’t go through them one by one on this occasion as there is a lot of technical details. My previous blog explains this in more details:

https://www.si-eng.org/blog/ciria-guide-c766-preview

The most significant one is the relaxation of allowable crack width for deep structures from 0.05mm to 0.1mm, as long as the water pressure on the structure is stable. The saving can be huge for deep structures. Although 0.05mm to 0.1mm seems small, it is a 100% change. The reinforcement saving from this change alone could be 50%.

So which one is ‘correct’?

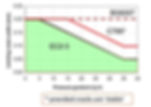

Whenever I look at this diagram, I couldn't help but ask – these 3 lines, they are three different solutions to the same problem. The nature of water-resisting concrete has never changed. The principles in the design of concrete structures has never changed. And yet there is a vast amount of difference between the three answers. So which one is the ‘correct’ answer?

Each of you may have your own verdict in your mind. Maybe none of them is ‘correct’; maybe they are all ‘correct’ in a way. I would be seriously interested in your opinion – if you have an opinion on it please leave me a comment.

We need to understand that calculations are only made to predict and manage the risk of cracking, regardless of how we crunch numbers, the real life outcome is influenced by many other factors in play.

Firstly, the design need to be realistic. Blindly throwing reinforcement at it can do more harm than good. Good detailing is particularly important for complex geometries. What’s more important is to try and have simple geometries in the first place.

Also, the contractor’s competence is equally important. We need Sound construction planning to reduce construction joints and restraint conditions, as well as good workmanship to execute the plan.